Blog

Comparison of the Three Main Solid-State Battery Technologies

2025-07-17 | Eric

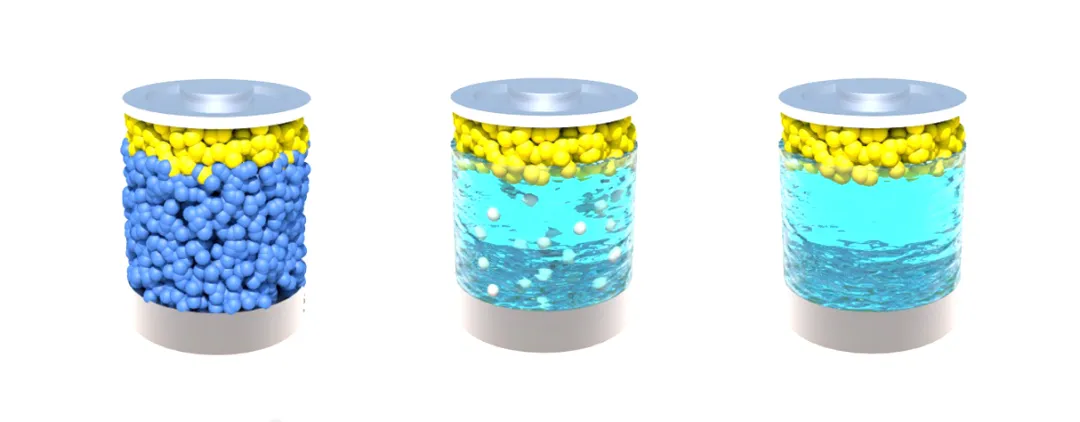

Solid-state batteries are generally categorized into three main technological routes based on the type of solid electrolyte material used: polymer electrolytes, oxide electrolytes, and sulfide electrolytes. Among them, sulfide electrolytes are widely regarded as the most promising direction for the development of all-solid-state batteries due to their outstanding electrochemical properties.

Ideally, solid electrolyte materials should possess the following characteristics:

- High ionic conductivity (comparable to or even exceeding that of liquid electrolytes)

- Excellent chemical and electrochemical stability with lithium metal anodes

- Effective suppression of lithium dendrite formation

- Simple and cost-effective manufacturing processes

- Minimal reliance on rare metal resources

However, none of the three mainstream technologies currently meet all of these criteria, and key technological breakthroughs are still needed before large-scale commercialization becomes feasible.

1. Polymer Electrolytes

Advantages: Easy to process and mold, compatible with existing battery manufacturing equipment and processes, flexible with excellent mechanical properties, and relatively mature technology that has been applied in some mass-produced products.

Disadvantages: Low ionic conductivity, especially under low temperatures; typically requires operating temperatures above 60°C. Poor chemical stability, making it difficult to pair with high-voltage cathode materials. Poses fire risks at high temperatures. Narrow electrochemical window (< 4V) and prone to decomposition, which limits its performance ceiling.

Applications: Mostly used in small-scale battery fields with low energy density and temperature control requirements, such as wearable devices and electric shavers.

2. Oxide Electrolytes

Advantages: Excellent conductivity and thermal stability, capable of withstanding temperatures up to 1000°C. Good mechanical and electrochemical stability. Abundant raw materials and strong adaptability.

Disadvantages: Ionic conductivity is still lower than sulfides, affecting high-rate discharge and capacity performance. High material hardness results in poor interfacial contact between the electrodes and electrolyte, increasing porosity and contact resistance. Requires high pressure for compression molding, making the process complex and difficult to achieve at room temperature.

Applications: Commonly used in semi-solid-state battery solutions that aim to balance safety and performance.

3. Sulfide Electrolytes

Advantages: Highest ionic conductivity, reaching up to 10⁻² S/cm—comparable to or even surpassing that of liquid electrolytes. Good interfacial contact with low interfacial resistance, enabling high energy density. Wide electrochemical window (over 5V), suitable for high-voltage applications. Excellent plasticity, aiding the formation of high-density battery structures.

Disadvantages: Prone to side reactions with electrode materials, resulting in poor interface stability that requires additional interfacial modifications. Highly sensitive to processing conditions, with strict environmental requirements. Reacts with moisture and oxygen in the air to release toxic hydrogen sulfide (H₂S). High material costs, and core materials such as lithium sulfide are price-sensitive and still require cost reduction.

Applications: Best suited for all-solid-state batteries and considered the optimal technological path to achieving high energy density and high safety.

Comparison Table of the Three Solid-State Electrolyte Technologies

| Category | Polymer Electrolyte | Oxide Electrolyte | Sulfide Electrolyte |

|---|---|---|---|

| Ionic Conductivity | Low | Medium | High |

| Mechanical Properties | Good | Very Hard | Good |

| Chemical Stability | Poor | Good | Average (requires interface optimization) |

| Electrochemical Window | Narrow (<4V) | Moderate | Wide (>5V) |

| Processing Difficulty | Low | Medium | High (requires moisture/oxygen control) |

| Commercialization Progress | Earliest, already mass-produced | In progress | Most potential, still in R&D |

Conclusion and Outlook

From current development trends, polymer electrolytes are the most mature and were developed earliest, with some commercial applications already realized. However, due to issues with conductivity and high-temperature safety, they have not yet achieved large-scale adoption. Oxide electrolytes offer balanced performance and are suitable for semi-solid-state battery development, with steady technological progress. Sulfide electrolytes, with the highest performance potential, are widely regarded as the key material to propel all-solid-state batteries into industrialization.

In the future, whether breakthroughs can be made in improving material stability, interface optimization, and cost control will directly determine if solid-state batteries can transition from laboratory research to mass production—leading the next revolution in energy technology.

Popular Articles

Contact Details

Worktime :Monday to Friday 9am - 6pm (HKT)

WhatsApp/Wechat/Mobile :+86XXXXX

Email : info@lifepo4cellstore.com