Blog

LiFePO4 Batteries vs Sealed Lead Acid Batteries: A Complete Comparison

2025-08-16 | Eric

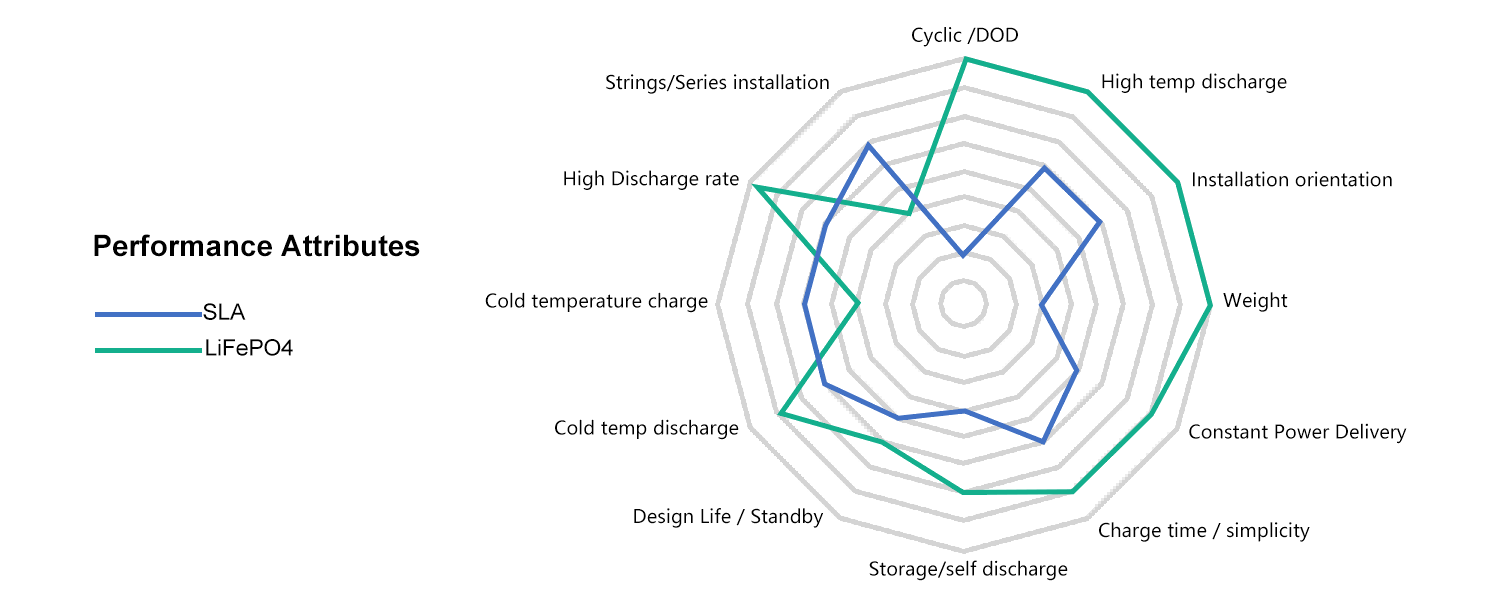

When you’re sizing a battery bank for a golf cart, backup power, marine use, or solar storage, the chemistry you choose changes everything — weight, runtime, maintenance and total lifetime cost. This piece gives a clear, practical comparison between LiFePO4 (LFP) and sealed lead-acid (SLA) batteries so you can pick the right tool for the job.

Usable energy: Depth of Discharge (DoD) matters

Don’t size batteries by nameplate amp-hours alone — usable energy depends on how deep you can safely discharge.

- SLA: Manufacturers typically recommend limiting DoD to ~30–50% to avoid shortened life. That means a 100 Ah SLA gives you ~30–50 Ah of reliable usable capacity if you want it to last.

- LiFePO4: Designed for deep cycling — 80% DoD is commonly used in system designs (many LFP packs are built for 80–100% usable capacity depending on the BMS and warranty). So a 100 Ah LFP battery often yields ~80 Ah usable without hurting cycle life.

Why it matters: You’ll need far fewer LFP amp-hours to deliver the same usable energy, which saves space and weight and reduces balance-of-system costs.

Efficiency and charge behavior — don’t waste your generation

Round-trip efficiency tells you how much stored energy you actually get back.

- LiFePO4 systems typically achieve >90–95% round-trip efficiency, meaning little energy is lost when charging/discharging.

- SLA banks commonly run closer to 70–85% efficiency in real systems.

Higher efficiency directly reduces how much solar or generator capacity you need for the same usable kWh — a practical win for LFP in solar and microgrid systems.

Cycle life & lifetime cost — the numbers that bite

Cycle life (how many full charge/discharge cycles the battery will tolerate) drives replacement cost and downtime.

- SLA: depending on type and DoD, typical cycle-life figures range from a few hundred up to around 1,000 cycles for deep cycles. Frequent deep discharge accelerates failure.

- LiFePO4: high-quality LFP packs commonly deliver thousands of cycles — many datasheets and field studies quote figures from ~2,500 up to 5,000+ cycles at sensible DoD levels. That often equates to a lifespan many times longer than SLA in cyclic use.

Bottom line: LFP’s higher upfront price is usually offset by fewer replacements, less labor to swap batteries, and lower lifecycle cost per kWh delivered.

Size, weight and practical packaging

LFP packs are far lighter and more energy-dense than lead-acid. Typical practical energy densities put LFP several times higher on a Wh/kg basis — that makes LFP the go-to for vehicles, marine craft, carts, and any application where mass and space matter. You’ll also get more flexible mounting options with lithium packs.

Maintenance & operational hassle

- SLA: even sealed types can suffer sulfation if left partially charged for long periods; flooded types need distilled water topping and ventilation. Terminals corrode, and routine checks add labor.

- LiFePO4: maintenance-free in normal use. Built-in BMS handles cell balancing, over/under-voltage protection and temperature limits, which reduces site visits and simplifies storage.

If you value “fit-and-forget” systems, lithium wins hands down.

Safety and temperature performance

LiFePO4 is among the safest lithium chemistries — it’s more resistant to thermal runaway than many nickel/cobalt chemistries and tolerates abuse better in standard tests. That’s why automakers and large-scale ESS vendors increasingly prefer LFP where safety and cost trade-offs fit. Still, all batteries need sensible thermal management: freezing temperatures can limit charge acceptance for LFP and high heat accelerates aging for any chemistry.

Environmental impact & recycling

- SLA: lead-acid is recyclable and there are well-established collection streams worldwide — but lead is toxic, and improper handling causes serious pollution risks.

- LiFePO4: LFP uses iron and phosphate (no cobalt or lead in the cathode) and generally has a lower toxicity profile. Recycling programs for lithium batteries are growing, and the longer service life of LFP reduces material throughput per delivered kWh. Still, proper end-of-life recycling is essential.

When to pick SLA (short list)

- Extremely limited capital and the battery will be used infrequently (rare emergency backup).

- Legacy systems where replacing the entire balance-of-system (BMS, chargers, inverter) for lithium would cost more than occasional SLA replacements.

If you expect regular cycling, mobility needs, or want low maintenance, SLA is rarely the best choice anymore.

Quick procurement checklist (do this before you buy)

- Define duty cycle: daily cycles, weekly, or standby? That determines preferred chemistry.

- Size by usable kWh: use ~80% DoD for LFP and ~30–50% DoD for SLA in your calculations.

- Compare lifetime cost: include expected replacements, installation, and maintenance.

- Inspect BMS features: cell balancing, temp cutoffs, communication (CAN/RS485) and warranty terms.

- Plan thermal management: shade, ventilation, or heaters for cold climates.

Conclusion

For most new installations in 2025 — especially where cycling, weight or maintenance matters — LiFePO4 (LFP) offers the best mix of performance, safety and lifecycle economics. SLA still has a role for very low-use, low-capex situations, but it’s an increasingly niche choice.

Popular Articles

Contact Details

Worktime :Monday to Friday 9am - 6pm (HKT)

WhatsApp/Wechat/Mobile :+8613645616165

Email : info@lifepo4cellstore.com