Blog

Latest Trends in Large-Capacity Energy Storage Cells

2026-01-25 | Eric

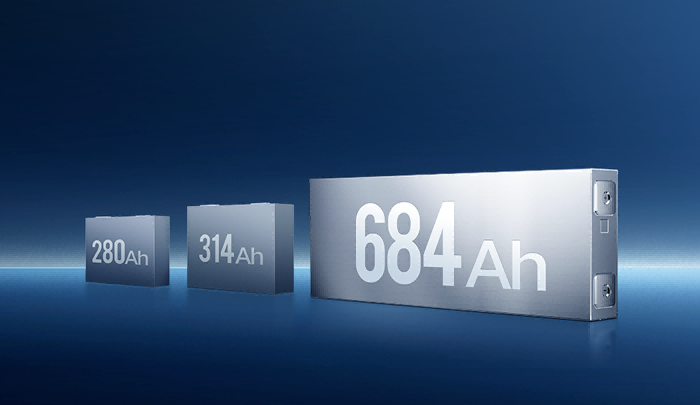

As the global energy structure accelerates its transition toward renewable energy, energy storage systems (ESS) have become a critical link in balancing grid fluctuations and enhancing green power consumption. In this context, the demand for cost reduction and efficiency improvement is increasingly urgent. Consequently, the upsizing of battery cells has become the core of industrial competition—evolving from 280Ah and 314Ah to the debut of 500Ah+ and even 600Ah+ products, significantly shortening iteration cycles. However, while large-format cells reduce system costs, they also face a series of technical challenges and must undergo rigorous verification by investors regarding life-cycle safety and economic viability. This article analyzes the internal logic and future direction of large-cell development from technical, market, and manufacturing dimensions.

01 Current Landscape of Large-Cell Layouts

With the intensifying need for cost reduction and efficiency in energy storage, battery cells are trending toward larger capacities. Currently, nearly 20 battery manufacturers have launched 500Ah+ products or related roadmaps, accelerating the industry's iteration process.

The transition of energy storage cells from 280Ah to 300Ah+ took approximately three years; however, the leap from 300Ah+ to 500Ah+ or even 600Ah+ took only two years.

- CATL is consolidating its dominance in large-scale energy storage power plants with 587Ah cells, attempting to enhance integrated service capabilities through "high-capacity standards."

- Sungrow, acting as a system integrator, has "reverse-defined" a 684Ah cell, building differentiated competitiveness through "cell-system" collaborative design.

- CALB and REPT are focusing on the 392Ah specification to seek rapid market entry.

While the move toward larger capacities by cell manufacturers and system integrators is an irreversible trend, it is too early to determine if project investors fully endorse these ultra-large capacities. Continuous market verification is required to identify the true strengths of large-capacity cells.

02 Why Pursue Large-Capacity Cells?

The battery cell represents the highest value segment of the energy storage system and is the primary battlefield for iteration in integration technology. It directly determines the system’s grouping methods and integration schemes.

The core essence of large-format cells is to reduce the quantity of batteries and components, as well as the physical footprint, thereby lowering the comprehensive investment cost of the power station.

For example, CATL’s 587Ah cell can reduce the number of system components by 20% and increase space utilization by 30%. With fewer cells, the costs of auxiliary materials—such as connectors, fuses, and BMS sampling harnesses—are significantly reduced.

From an Operations and Maintenance (O&M) perspective, for a system of the same capacity, the use of large cells results in significantly fewer units. This means fewer potential points of failure, lower complexity in monitoring and maintenance, and a reduction in life-cycle O&M costs.

03 Technical Challenges Facing Large Cells

During the charging and discharging process, when cell capacity exceeds 500Ah, the electrode thickness often increases from 150μm to 250μm. This extends the diffusion distance of Li within the LiFePO4 lattice, hindering electrochemical reactions. This leads to increased polarization voltage at the end of charging, accelerating cell aging and shortening service life.

Furthermore, elevated polarization voltage generates excessive internal heat, which may trigger thermal runaway, leading to safety incidents such as fires or explosions.

Manufacturing and Integration Hurdles:

- Manufacturing Process: Large electrodes require extremely high coating uniformity; thickness deviations increase with size. Larger tab welding areas increase the probability of pseudo-welding or burn-through. Uneven current distribution during the formation process can lead to variations in SEI film generation, affecting life-cycle consistency.

- System Integration: The importance of a single cell increases significantly. In a 314Ah system, a single-cell failure affects about 0.3% of the cluster capacity; in a 684Ah system, that impact rises to 0.6%.

- Thermal Management: Large cells have longer heat dissipation paths and higher thermal resistance. To compensate, liquid cooling systems require higher flow rates and pressure, demanding higher reliability from cooling components.

Currently, 314Ah systems are mature. For investors, the safety and stability of larger cell integrated solutions often only exist in laboratory reports. Without long-term reliable operating data, widespread acceptance may face difficulties in the short term.

04 Manufacturing Processes: Winding vs. Stacking

Discrepancies in R&D focus have led to a divergence in manufacturing routes for 500Ah+ cells, primarily between Winding and Stacking.

| Process | Advantages | Disadvantages |

|---|---|---|

| Stacking | Laminated structure with no electrode bending; higher energy density; lower internal resistance and temperature rise; better rate performance and safety. | Risk of internal short circuits due to burrs/dust at cut edges. Requires high-precision equipment; higher equipment and production costs. |

| Winding | High production efficiency; simpler operation with fewer welds; lower equipment investment costs. | Single-tab design leads to higher internal polarization and poorer rate performance. Uneven tension can cause wrinkles, affecting cycle life. |

05 Standardization vs. Differentiation

Following the issuance of Document No. 136 by the Chinese government, the marketization of energy storage investment has accelerated. Investors are now more focused on Life-Cycle Economic Efficiency. As the industry reaches a consensus on "thermal runaway warning thresholds" and "cycle life baselines," a safety benchmark for different cell sizes has emerged. Additionally, the unification of BMS communication protocols allows different cell sizes to be integrated into the same monitoring system.

In the short term, different market priorities regarding capacity, density, cost, and safety are driving design divergence:

- 314Ah and 392Ah cells will continue to dominate the 2h and 4h storage markets.

- 500Ah+ cells will focus on long-duration energy storage (LDES) of 4h or more.

Tier-1 companies tend to define next-generation sizes with a single specification, while Tier-2 and Tier-3 companies adopt multi-specification strategies to meet diverse customer needs, resulting in a "let a hundred flowers bloom" landscape.

06 Future Outlook

Cell development should not blindly pursue "larger size." It must consider investor acceptance and balance technical innovation across the storage system, AC-side distribution, and O&M to achieve a lower Levelized Cost of Storage (LCOS).

Although 500Ah+, 700Ah+, and even 1000Ah+ cells are being launched, they have not yet achieved large-scale installation. It is too early to judge the ultimate winner. The successful product will be determined by a company's deep understanding of system boundaries, rational judgment of technical tipping points, and flexible response to diverse application scenarios.

Popular Articles

Contact Details

Worktime :Monday to Friday 9am - 6pm (HKT)

WhatsApp/Wechat/Mobile :+8613645616165

Email : info@lifepo4cellstore.com